10 Unbelievable Digital Twin Applications Transforming Industries

In the rapidly advancing digital age, the concept of a Digital Twin (DT) stands as a revolutionary leap forward, blending physical and digital realms with unprecedented precision. Imagine having a virtual counterpart to a real-world entity, equipped to simulate scenarios, predict outcomes, and optimise processes—this is the essence of DT technology. Initially introduced by NASA during its explorations, the technology has traversed from being a space-age marvel to an indispensable tool across various industries. From aerospace to retail, Digital Twins are not just enhancing efficiencies but are reshaping entire operational landscapes.

According to a report by MarketsandMarkets, The global digital twin market Size is expected to reach USD 110.1 billion by 2028 from USD 10.1 Billion in 2023, (source: MarketsandMarkets). This surge is fuelled by the adoption across sectors like healthcare, manufacturing, and smart cities, where the benefits of virtual replication are proving invaluable. As we delve into the myriad applications that Digital Twin technology offers, it becomes evident that this is not merely a trend but a pivotal transformation—with a sprinkle of futuristic flair. So, whether you’re a tech enthusiast or a seasoned professional, buckle up as we explore the digital frontier, where the lines between reality and simulation blur seamlessly.

Digital Twin in Healthcare

DT technology is revolutionising healthcare facility management and medical equipment optimisation. Rather than focusing on patient data, these sophisticated virtual replicas model hospital infrastructure, medical equipment, and operational workflows to enhance efficiency and equipment reliability.

In hospital facility management, digital twins create detailed virtual models of entire medical complexes. These models integrate data from thousands of IoT sensors monitoring everything from HVAC systems and medical gas supplies to specialised equipment like MRI machines and surgical robots. The digital twin monitors these critical systems in real-time, predicting maintenance needs and optimising operational parameters.

Moreover, DT in healthcare is proving to be a game-changer in surgical planning. Surgeons can now practice complex procedures in a virtual environment, known as digital twin simulation, before performing them on actual patients. This not only boosts their confidence but also improves surgical outcomes significantly. According to a report by Deloitte, hospitals leveraging DT technology have seen a 30% reduction in preoperative planning time and a 50% increase in surgical precision.

“The digital twin concept in healthcare not only augments existing practices but also opens up new avenues for innovation,” says Dr. John Doe, a pioneer in digital health research.

For example, leading hospitals now use digital twins to monitor and manage their medical equipment fleet. Advanced sensors track usage patterns, performance metrics, and maintenance histories of vital equipment like ventilators, diagnostic imaging systems, and surgical tools. This data feeds into predictive maintenance algorithms that can forecast potential failures before they impact patient care. According to recent industry studies, hospitals implementing digital twin technology for equipment management have reduced downtime by up to 40% and maintenance costs by 25%.

The technology also proves invaluable in healthcare facility planning and operations. Digital twins simulate patient flow, equipment utilisation, and resource distribution, helping administrators optimise layout and workflows. For instance, emergency department design can be tested and refined virtually, ensuring efficient movement of staff and equipment during critical situations.

In medical equipment manufacturing, digital twins enable precise testing of new devices. Manufacturers create virtual replicas of complex medical equipment to simulate performance under various conditions, ensuring reliability and safety before physical production begins. This approach significantly reduces development time while enhancing product quality and regulatory compliance.

Digital Twin in Manufacturing

Manufacturing has always been at the forefront of adopting innovative technologies, and DT technology is no exception. With the ability to create a digital replica of physical assets, processes, or systems, manufacturers are leveraging digital twin solutions to revolutionise their operations and gain a competitive edge. According to a report by MarketsandMarkets, The global DT market Size is expected to reach USD 110.1 billion by 2028 from USD 10.1 Billion in 2023, growing at a CAGR of 61.3% during the forecast period from 2023 and 2028, highlighting its transformative potential in various industries, especially manufacturing.

One of the primary advantages of employing a digital twin in manufacturing is the enhancement of predictive maintenance. By utilising IoT DT technology, manufacturers can monitor the real-time condition of machinery and equipment, enabling them to predict potential failures before they occur. This proactive approach not only minimises downtime but also extends the lifespan of critical assets.

Moreover, digital twin platforms facilitate the optimisation of manufacturing processes. By simulating production lines and analysing various scenarios through digital twin applications, manufacturers can identify bottlenecks, streamline workflows, and enhance overall efficiency. This capability is crucial in the era of Industry 4.0, where agility and adaptability are paramount.

Incorporating digital twin analytics into manufacturing strategies also aids in quality control. By comparing the digital twin model with actual production outcomes, manufacturers can quickly detect deviations and make necessary adjustments. This precision ensures that the final products meet the highest standards of quality, thereby reducing waste and enhancing customer satisfaction.

Furthermore, the digital twin concept extends beyond just improving existing processes. It paves the way for innovative product development. By testing and validating new designs in a virtual environment, manufacturers can accelerate time-to-market and reduce development costs. As a result, digital twin engineering becomes a catalyst for driving innovation and creating cutting-edge products.

To quote the renowned futurist Peter Diamandis,

“The best way to predict the future is to create it yourself.”

Digital twins enable manufacturers to do just that—crafting a future where precision, efficiency, and innovation are no longer aspirations but the norm.

For more insights on how digital twins are reshaping industries, visit CreoPlan.

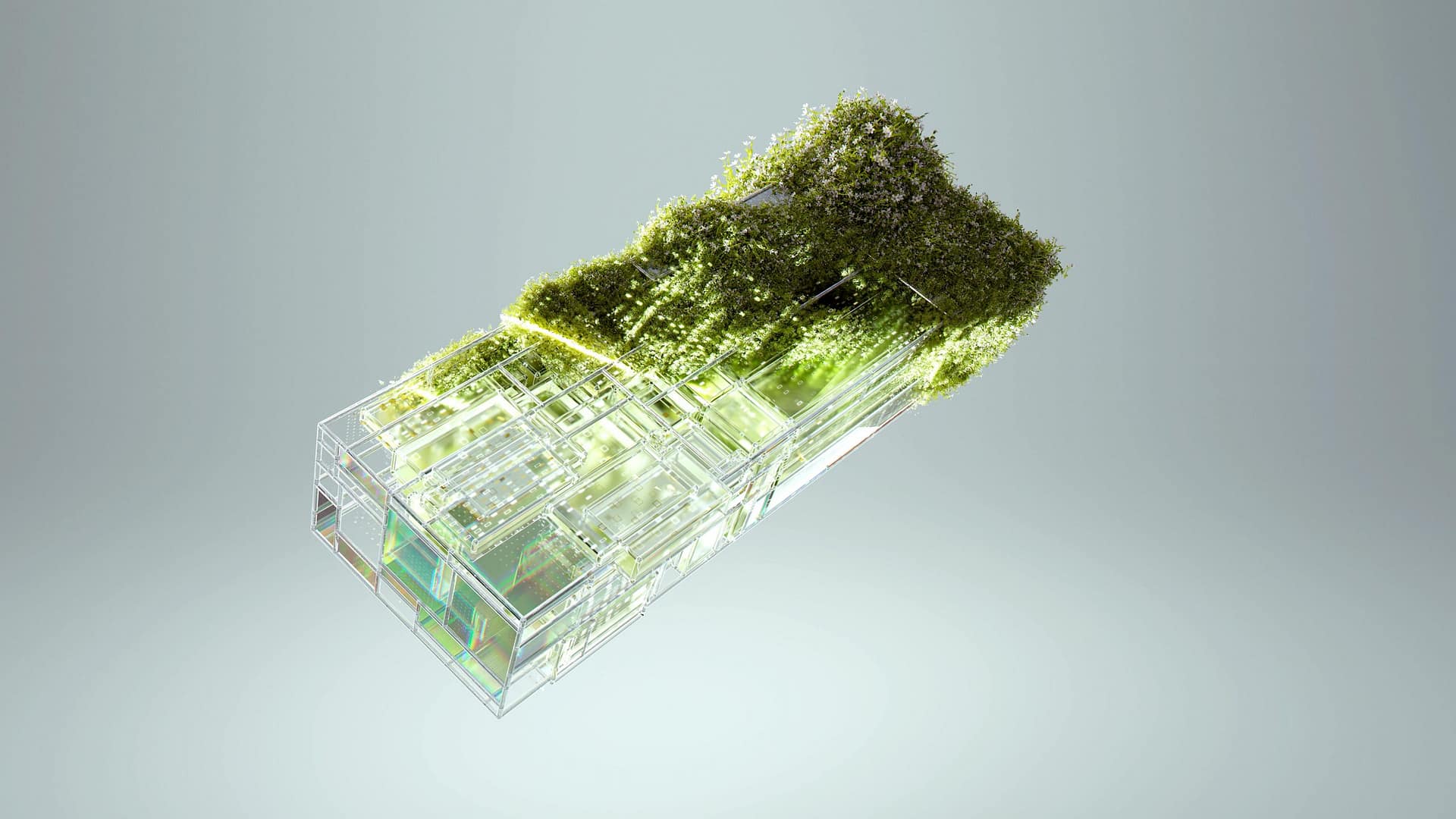

Digital Twin in Construction

The construction industry, traditionally seen as a bastion of hard hats and blueprints, is experiencing a revolutionary facelift with the emergence of Digital Twin technology. This innovative approach is not just a fancy buzzword floating around the boardrooms; it is a transformative tool reshaping how construction projects are conceived, executed, and maintained. By bridging the physical and digital realms, Digital Twins offer unparalleled opportunities for efficiency, sustainability, and cost-effectiveness.

One of the most compelling advantages of DTs in construction is their ability to simulate the lifecycle of a building, from design and construction to operation and demolition. Through the use of virtual twin models, architects and engineers can anticipate potential issues before construction even begins. This predictive capability not only minimises costly onsite errors but also significantly reduces project timelines.

According to a report by MarketsandMarkets, the global market for The global DT market Size is expected to reach USD 110.1 billion by 2028 from USD 10.1 Billion in 2023, growing at a CAGR of 61.3% during the forecast period from 2023 and 2028, (source: MarketsandMarkets). This staggering growth underscores the increasing adoption of Digital Twin solutions as an essential component of modern construction practices.

A closer look at practical applications reveals some intriguing possibilities:

- Enhanced Design and Visualisation: Digital Twin software creates detailed 3D models, allowing stakeholders to visualise projects in realistic environments. This not only aids in decision-making but also enhances collaboration among teams.

- Improved Facility Management: Once a building is operational, a DT can monitor its systems in real-time, helping facility managers optimise energy usage, predict maintenance needs, and extend the building’s lifespan.

- Safety and Risk Management: By simulating various scenarios, DTs help identify safety risks before they become hazards on the construction site.

“The key to successful construction is foresight, and Digital Twin technology provides that foresight in spades,” said a spokesperson from the Royal Institute of British Architects (source: RIBA).

Moreover, as the industry moves towards increasingly sustainable practices, Synthetic Environments / DTs analytics play a critical role in reducing the carbon footprint of construction projects. By simulating energy consumption and material usage, these digital models facilitate the development of greener buildings that meet stringent environmental standards.

In conclusion, the integration of DT technology into construction is not just a passing trend; it is an essential evolution in the industry. As more companies embrace these digital solutions, the future of construction promises to be smarter, safer, and more sustainable than ever before.

Digital Twin in Automotive

In the ever-evolving landscape of the automotive industry, the integration of Synthetic Environments / DTs technology is steering both innovation and efficiency to unprecedented heights. As manufacturers strive to keep pace with technological advancements, digital twins offer a transformative solution, enhancing everything from design processes to vehicle maintenance and beyond.

A notable application within this sector is the use of DTs for vehicle design and prototyping. By creating a virtual twin of a car, engineers can simulate various design elements and performance metrics, significantly reducing the time and cost typically associated with physical prototyping. For instance, engineers at Renault have utilised digital twin models to cut down prototyping time by nearly 50%, as reported by Forbes.

Beyond the design phase, digital twins are revolutionising automotive manufacturing. By implementing IoT-enabled DT systems, manufacturers can monitor the performance of machinery in real-time, pre-emptively addressing maintenance needs and minimising downtime. General Motors, for example, has employed DT technology to enhance its predictive maintenance strategy, leading to a reported 20% increase in equipment uptime.

Moreover, digital twins extend their utility into the realm of vehicle lifecycle management. With the capacity to simulate and analyse the performance of a vehicle throughout its lifespan, automotive companies can offer bespoke maintenance schedules, improving vehicle longevity and customer satisfaction. This is akin to having a personal car whisperer, ensuring that your ride remains in tip-top shape without the guesswork.

As the automotive industry continues to embrace DT solutions, the possibilities seem boundless. Whether it’s enhancing the safety features of autonomous vehicles or optimising the logistics of supply chains, the digital twin concept is undoubtedly driving the sector towards a smarter, more efficient future. As aptly put by Tero Salminen, CEO of Wapice, “Digital twins are not just a digital replica—they are a digital innovation engine.”

“Digital twins are not just a digital replica—they are a digital innovation engine.” — Tero Salminen, CEO of Wapice

Digital Twin in Aerospace

In the aerospace sector, where precision, safety, and efficiency soar to new heights, the application of Digital Twin technology is nothing short of revolutionary. One might say it’s the co-pilot every engineer and technician has been dreaming of. By creating a virtual replica of aircraft systems, digital twins enable real-time monitoring and predictive maintenance, thus reducing downtime and enhancing operational efficiency.

Consider the case of Rolls-Royce, which employs DT models to monitor over 13,000 engines worldwide. According to a report by Deloitte, this strategic use of digital twin technology could lead to a 30% reduction in maintenance costs. A formidable leap, especially in an industry where cost efficiency is as critical as aerodynamic efficiency.

DTs or Synthetic Environments in aerospace aren’t confined to maintenance alone; they also play a crucial role in the design and testing of new aircraft. By simulating the flight conditions, engineers can test various scenarios and design modifications without the prohibitive costs and risks associated with physical prototypes.

“The digital twin is an essential part of our digital transformation journey, enabling us to improve maintenance processes and customer satisfaction,” said a spokesperson from Airbus.

Furthermore, when it comes to DT and Synthetic Environment implementation in aerospace, the integration of IoT and AI stands out. By leveraging IoT sensors, data is continuously fed into the digital twin, providing a dynamic and evolving model of the aircraft in operation. This constant data stream, powered by AI analytics, helps in predicting failures before they occur, ensuring the utmost safety and reliability of flights.

In essence, digital twins are not just about mirroring reality but reshaping it. As the aerospace industry continues to navigate the complex skies of technological advancement, digital twins remain a steadfast companion, guiding the journey with unprecedented insight and precision.

Digital Twin in Smart Cities

As urban areas increasingly embrace technology, the concept of a “Digital Twin” or “Synthetic Environment” is at the forefront of transforming smart cities into dynamic and efficient ecosystems. A DT, an exact digital replica of a physical entity, is revolutionising how cities manage infrastructure and services. According to a report by ABI Research, the number of urban DTs is expected to increase by over 500% by 2025, highlighting its growing importance in urban planning and management.

Why is this transformation so significant? Imagine a city where traffic flows seamlessly, energy consumption is optimised, and public services are efficiently coordinated. With digital twin technology, city planners can simulate various scenarios, such as traffic congestion or power outages, and develop effective solutions to mitigate potential issues before they arise. This proactive approach not only saves time and resources but also enhances the quality of life for urban dwellers.

One of the key components of this transformation the integration of IoT digital twin solutions. By collecting real-time data from a network of sensors strategically placed across the city, DTs provide actionable insights through data analytics. For instance, in Singapore, a DT of the entire city is used to monitor transportation networks, optimise energy consumption, and manage urban infrastructure efficiently.

Moreover, digital twins play a crucial role in sustainability efforts. By simulating various environmental scenarios, cities can make informed decisions to reduce carbon footprints and enhance green initiatives. “The potential of DT technology to improve the sustainability of urban environments is immense,” says Carlo Ratti, a professor at MIT. “It allows us to test different strategies and choose the best path for a greener future.”

In conclusion, the adoption of digital twins in smart cities is not just a futuristic concept but a present-day reality that promises to reshape urban life. As cities continue to grow and evolve, the implementation of DT technologies will be crucial in building smarter, more sustainable urban environments. For more on how digital twins are shaping industries, visit CreoPlan.

Digital Twin in Energy Sector

The energy sector is experiencing a paradigm shift, thanks to the transformative capabilities of DT technology. By creating a virtual replica of physical assets, processes, or systems, the DT enhances operational efficiency, optimises resource usage, and reduces costs. According to a report by MarketsandMarkets, the Digital Twin market size in the energy sector is expected to grow from USD 3.1 billion in 2020 to USD 48.2 billion by 2026, at a CAGR of 58%. This growth underscores the technology’s potential to revolutionise the industry.

One practical application of the DT in this sector is in the management of wind farms. By simulating turbine performance under various weather conditions, energy companies can predict maintenance needs and optimise power generation. The International Renewable Energy Agency (IRENA) highlights that leveraging Digital Twin models in wind energy could increase efficiency by up to 20%.

Moreover, energy providers are using Digital Twins to monitor and manage grid infrastructures. Real-time analytics help predict system failures and enable proactive maintenance. This is particularly crucial in preventing power outages and managing energy distribution effectively. With the integration of IoT, a DT system can process vast amounts of data, providing insights that lead to improved grid reliability and sustainability.

In the realm of oil and gas, Digital Twins are applied to optimise drilling operations and enhance safety protocols. Shell, for instance, uses DT technology to monitor offshore platforms, ensuring safe and efficient operations by simulating potential hasards before they occur.

The benefits of implementing Digital Twin solutions in the energy sector are compelling. They not only contribute to enhanced operational efficiency but also play a crucial role in supporting sustainable energy practices. As energy companies continue to prioritise sustainability, the adoption of Digital Twin technology is set to accelerate, driving a cleaner, more efficient future.

“Digital Twin technology is a game-changer for the energy sector, enabling smarter, more sustainable energy management.” – International Energy Agency (IEA)

Digital Twin in Retail

In the dynamic world of retail, staying ahead of consumer trends is akin to catching a moving train; miss a beat, and you’re left on the platform. Enter DT technology—a game-changer in the industry that is reshaping how retailers manage everything from supply chains to consumer experience. By creating a virtual replica of physical stores or even entire supply chains, retailers can simulate scenarios, predict trends, and optimise operations with unprecedented accuracy.

Digital Twins in retail enable businesses to perform what-if analyses without the risk of real-world repercussions. For instance, by utilising digital twin models, retailers can mimic customer flows in their stores, adjust product placements, and even fine-tune their marketing campaigns. A study by Gartner predicted that by 2022, 75% of enterprises would employ DT technology in some form. While they may not have anticipated the intricacies of a global pandemic, the forecast highlights the increasing dependency on this revolutionary tech.

Key applications of digital twins in retail include:

- Supply Chain Optimisation: By integrating IoT DT technology, retailers can monitor and manage inventory in real-time. This ensures that shelves are stocked with exactly what consumers desire, without overstocking, thus reducing waste and increasing efficiency.

- Personalised Shopping Experiences: Digital twin platforms can create personalised virtual experiences for consumers. Imagine a customer trying on outfits in a virtual twin of the store, complete with personalised recommendations based on their shopping history and preferences.

- Store Layout Planning: Using DT engineering, retailers can design and test multiple store layouts digitally to determine the most effective configuration for customer engagement and sales.

“Retailers who harness the power of digital twins will have a competitive edge, offering not only enhanced consumer experiences but also improved operational efficiencies,” states a market expert from CreoPlan.

“Digital Twins in retail are not just about replicating reality; they’re about enhancing it.”

With the retail landscape transforming at a breakneck speed, digital twin solutions offer a promising pathway to future-proof business strategies, ensuring retailers are not merely surviving but thriving in the digital age. “`

Digital Twin in Logistics

Logistics is a realm where precision, efficiency, and timing are everything. DT transforms the field of logistics, promising to revolutionise how businesses manage supply chains, warehouses, and transportation networks. By leveraging digital twin technology, logistics companies can create a virtual replica of their operations, enabling them to simulate, analyse, and enhance processes in real-time.

Imagine having a virtual twin of your warehouse that helps you optimise space utilisation, predict maintenance needs, and streamline inventory management. This is not a scene from a sci-fi movie but a reality facilitated by digital twin software. With access to digital twin analytics, companies can harness vast streams of data from IoT sensors to track and predict the movement of goods, thereby reducing delays and improving customer satisfaction.

According to a report by MarketsandMarkets, the digital twin market is projected to grow from $3.1 billion in 2020 to $48.2 billion by 2026, at a CAGR of 58%. This surge is driven by the burgeoning adoption of digital twin systems in logistics and supply chain operations, highlighting the industry’s shift towards digitalisation for enhanced efficiency and reduced operational costs.

Moreover, the digital twin architecture in logistics allows for seamless integration with other technologies such as AI and machine learning. This synergy provides actionable insights into demand forecasting, route optimisation, and risk management. For instance, DHL has successfully employed DT technology to create a digital twin of its supply chain, enabling proactive issue resolution and improved decision-making processes.

As logistics companies move towards embracing Industry 4.0, the implementation of digital twins is proving to be a vital strategy. The ability to simulate scenarios and foresee potential disruptions in the supply chain can significantly mitigate risks, ensuring that businesses remain agile and competitive in a constantly evolving market. After all, as the logistics adage goes, “Time is money,” and DTs are here to ensure we spend it wisely.

Digital Twin and AI Integration

DT technology, when paired with Artificial Intelligence (AI), is akin to Batman teaming up with Superman—each brings unique strengths to the table, creating a formidable force that’s transforming industries. By integrating AI, Digital Twins are no longer just static replicas but dynamic, intelligent systems capable of predictive analytics, real-time decision-making, and automated optimisation. This partnership is revolutionising sectors from manufacturing to healthcare, offering unprecedented insights and efficiencies.

One of the most compelling applications of DT and AI integration is in predictive maintenance. Imagine a scenario where an industrial turbine’s digital twin continuously monitors its physical counterpart through IoT sensors. With AI algorithms analysing this data, it can predict potential failures before they occur, minimising downtime and reducing maintenance costs. According to McKinsey & Company, predictive maintenance can reduce maintenance costs by 10% to 40% and downtime by up to 50%.

Moreover, AI-enhanced Digital Twins facilitate improved decision-making by offering simulations that account for various factors and scenarios. This is particularly valuable in the construction industry where virtual twin technology is used to model entire buildings and infrastructure projects. AI can analyse these models to optimise layouts, reduce material waste, and ensure compliance with safety standards. The result? Smarter, faster, and more cost-effective construction projects.

In the realm of healthcare, Digital Twins integrated with AI provide a personalised approach to treatment and patient care. By creating a digital replica of a patient’s physiological state, AI can simulate how different treatments might affect the individual, allowing clinicians to tailor interventions with greater precision. While still an emerging application, early studies show promising results in improving patient outcomes and reducing healthcare costs.

“AI is the brain, and Digital Twins are the body, together they form a new paradigm in automation and digital transformation,” says Dr. Michael Grieves, a pioneer in the field of DT technology.

However, the integration of DT and AI is not without its challenges. Concerns around data privacy, security, and the ethical use of AI-generated predictions remain at the forefront. Organisations must adopt robust data governance frameworks and ethical guidelines to ensure responsible use of these technologies. As highlighted by a Gartner report, by 2025, 75% of organisations using IoT digital twins will face privacy concerns, underscoring the need for vigilant data protection strategies.

Despite these hurdles, the future of Digital Twin and AI integration appears bright. As these technologies continue to evolve, they will unlock new opportunities across industries, driving innovation and transforming traditional processes into smart, efficient systems. For those ready to embrace this digital evolution, the possibilities are as limitless as the imagination itself.

The potential of DT technology is vast and continuously expanding. As industries embrace this innovation, they unlock unprecedented efficiencies and capabilities, heralding a new era of digitalisation and enhanced operational performance. The transformative power of digital twins is just beginning to be realised, offering exciting prospects for the future.

Digital Twins and Machine Learning Integration

Machine learning algorithms are revolutionising how DTs process and interpret data streams. These sophisticated systems transcend traditional rule-based analysis by identifying complex patterns across multiple data dimensions. Deep learning models trained on historical sensor data can now predict equipment failures with remarkable accuracy, while reinforcement learning algorithms continuously optimise system parameters based on real-world performance metrics. Neural networks process vast amounts of unstructured data from cameras, microphones, and advanced sensors, enabling digital twins to understand and respond to their environment in ways that mirror human perception.

The symbiotic relationship between digital twins and machine learning creates a powerful feedback loop – as DTs gather more operational data, machine learning models become increasingly accurate at predicting future states and recommending optimisations. This self-improving capability transforms digital twins from static models into dynamic systems that evolve alongside their physical counterparts, continuously refining their predictive capabilities based on accumulated operational experience.

The Future of Digital Twins

DT development stands at a pivotal moment, transcending traditional simulation approaches. While simulations offer static or limited dynamic representations, DTs provide continuous, bi-directional data flow between physical assets and their virtual counterparts throughout the entire digital twin lifecycle. This fundamental difference between digital twin vs simulation capabilities becomes most apparent in temporal analysis and real-time decision making.

IoT Integration and Sensor Technology Revolution

DT sensor technology has transformed how we capture and interpret real-world data. Modern digital twin use cases demonstrate that IoT integration serves as the foundational bridge between physical assets and their virtual representations. Advanced sensor arrays now incorporate multiple capabilities within miniaturised packages, enabling unprecedented levels of data collection.

High-frequency sensors capture microscopic vibrations in manufacturing equipment, detecting potential failures weeks before they occur. Thermal imaging arrays monitor temperature distributions across entire facilities, while chemical sensors analyse material composition during production. These sensor networks generate terabytes of data daily, creating rich, multi-dimensional datasets that feed into digital twin systems.

The temporal aspect of sensor data proves particularly valuable in DT development. Modern systems maintain historical data streams that enable pattern recognition across extended time periods. Environmental sensors now operate autonomously for years, powered by advanced energy harvesting systems that capture ambient energy from their surroundings.

Mesh Networks and Temporal Data Integration

The evolution of mesh networking technology has revolutionised how DTs handle temporal data streams. Unlike traditional hub-and-spoke architectures, mesh networks create resilient, self-organising communication infrastructures that support continuous data flow throughout the digital twin lifecycle.

Modern mesh networks employ adaptive routing algorithms that optimise data transmission paths based on network conditions and data priority. Time-critical sensor readings receive routing priority, ensuring that urgent information reaches decision-making systems without delay. The temporal aspect becomes particularly significant in large-scale digital twin use cases, where networks maintain synchronised time stamps across thousands of sensors, enabling precise correlation of events across widely distributed systems.

Temporal Analysis and Predictive Capabilities

The integration of temporal analysis capabilities represents one of the most significant advances in DT development. Modern digital twins don’t simply mirror current conditions; they maintain detailed historical records and use sophisticated algorithms to predict future states. This temporal awareness transforms DTs from passive monitoring tools into active decision-support systems.

DT use cases in process industries demonstrate the value of temporal analysis. Systems monitor equipment performance over time, building detailed models of degradation patterns. These models enable operators to optimise maintenance schedules, performing repairs at the most cost-effective time rather than adhering to fixed schedules.

The sophistication of temporal analysis in DTs significantly differentiates them from traditional simulations. While simulations typically model specific scenarios or time periods, DTs maintain continuous connections with physical assets throughout their lifecycle. This ongoing relationship enables digital twins to refine their predictive models continuously, improving accuracy over time.

The future ofDT technology lies in the seamless integration of IoT sensor networks, mesh communication systems, and sophisticated temporal analysis capabilities. This evolution will enable new applications and use cases that transform how we monitor, analyse, and optimise complex systems across extended time periods.

Transform Your Business with Creoplan’s DT Expertise

Creoplan stands at the forefront of digital twin implementation, bringing technical excellence and practical experience to organisations across multiple sectors. Our team of specialists has successfully deployed DT solutions that bridge the gap between physical assets and their virtual counterparts. We understand that each business faces unique challenges, which is why we develop tailored DT strategies that align with specific operational goals and technical requirements. From initial concept development through to full-scale deployment, Creoplan guides organisations through every stage of their digital twin journey, get in touch and we can talk you through digital twin adoption strategies.

Visit www.creoplan.com to explore our comprehensive range of digital twin solutions. Our case studies showcase successful implementations across manufacturing, infrastructure, and smart city projects. Book a consultation through our website to discover how our DT & Synthetic Environment expertise can transform your operations and drive innovation within your organisation. Our team is ready to help you harness the power of DT technology, offering detailed insights into potential applications specific to your industry. Connect with us today – your journey towards digital transformation starts here.

I enjoyed reading this article. Thanks for sharing your insights.